Steel profile storage is an important link in industrial production, and different storage methods directly affect production efficiency, cost and safety. From the initial ground pile model to today’s advanced Electrically moving roll out cantilever racks, steel profile storage has undergone significant changes. Today I will discuss the changes of these storage methods and their advantages and disadvantages in detail, and introduce the advantages of Electrically moving roll out cantilever racks in modern steel profile storage.

the Origin and Dilemma of the Ground Pile Model

1. Simple and direct storage

In the early days of steel profile storage, the ground pile mode was a simple and direct storage method. The steel profile is piled on the open space at will, without the need for additional equipment and complex management. However, this approach also hides many problems.

2. Steel profile deformation and quality loss

When steel profile is stacked in the ground pile mode for a long time, it is easy to be affected by heavy pressure and environmental factors, resulting in deformation and quality loss. Especially in the case of open storage, natural conditions such as rain and sunlight will accelerate the oxidation and corrosion of steel profile, affecting the service life and performance.

3. Difficult to find and transport

In the ground pile mode, the search and handling of steel profile becomes extremely difficult. Workers need to find the required materials among mountains of steel profile, which is inefficient and prone to errors. At the same time, the steel profile stacking is unstable, increasing the safety risk in the handling process.

4. Low space utilization

Because of the disordered stacking of steel profile, it is difficult to effectively use the vertical space of the warehouse in the ground stacking mode, resulting in serious space waste. The warehouse looks full, but the actual storage capacity is far from being maximized.

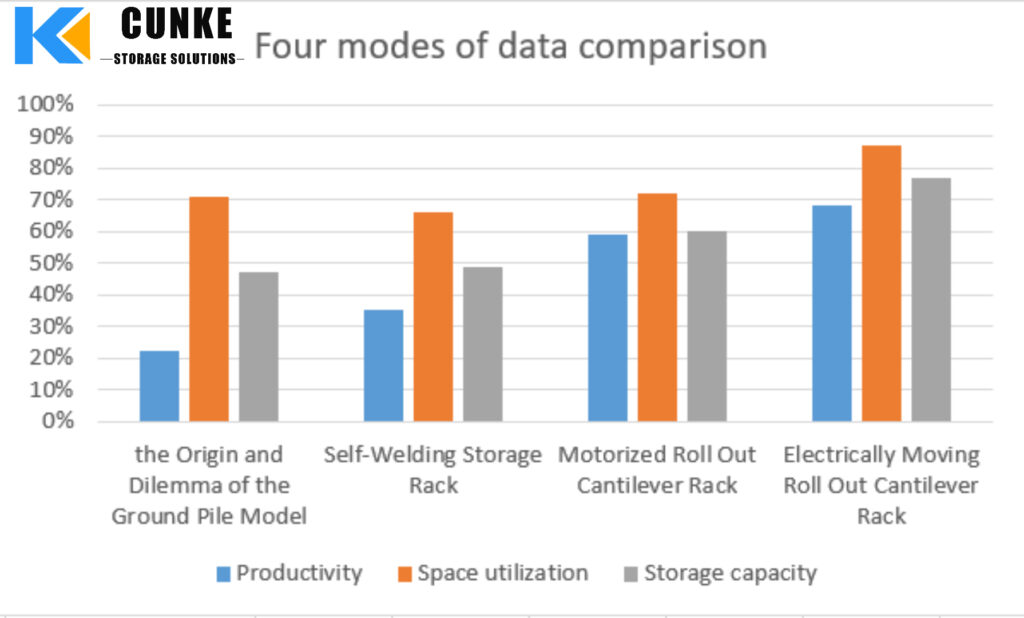

Efficiency indicators of the ground reactor mode:

• Storage capacity: 47%

• Productivity: 22%

• Space utilization: 71%

the Initial Attempt of Self-Welding Storage Rack

1. Improve the storage environment

In order to deal with the problems caused by the ground pile model, some companies have begun to try to weld their own storage racks. By putting steel profile on the rack for classified storage, the storage environment is improved and the possibility of deformation and wear is reduced.

2. Improve search efficiency

The classification storage method of self-welding storage rack improves the searching efficiency of steel profile. Workers can find the steel profile they need faster, reducing unnecessary time wastage and increasing production efficiency.

3. Load-bearing capacity and stability problems

However, self-soldering storage racks also have their limitations. Due to the limitation of welding process and materials, the bearing capacity and stability of the storage rack are difficult to guarantee, and there are security risks. Especially when storing a large amount or large weight of steel profile, the rack is prone to deformation or collapse.

4. Space utilization is not high

Although the self-welding storage frame has improved some of the problems, its space utilization is still not high. Different specifications of steel profile require different storage space, self-welding storage rack is difficult to adjust flexibly, resulting in space waste.

5. Low manual operation efficiency

The self-welding storage rack still needs manual operation when accessing steel profile, which is inefficient. Manual operation is not only time-consuming and labor-intensive, but also error-prone and difficult to meet the needs of modern production.

Efficiency index of self-welding storage rack:

• Storage capacity: 49%

• Efficiency: 35%

• Space utilization: 66%

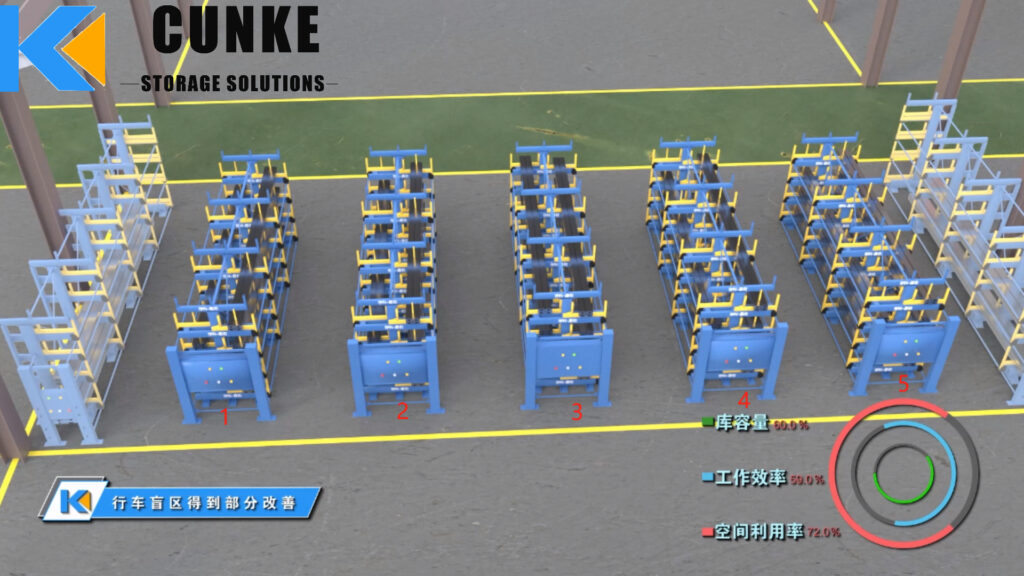

the Rise of Motorized Roll Out Cantilever Racks

1. High strength materials and precision manufacturing

With the progress of science and technology and the development of industrial automation, the Motorized Roll Out Cantilever Racks have gradually become the mainstream choice for steel profile storage. This kind of rack uses high-strength materials and precision manufacturing process to ensure the load-bearing capacity and stability of the rack. Whether it is to store heavy steel profile or use it for a long time, the rack can maintain good performance and safety.

2. Flexible to meet storage requirements

The Roll Out Cantilever Rack can adjust the height and cantilever length according to actual needs, and flexibly adapt to different specifications and quantities of steel profile storage needs. This flexibility makes it suitable for a variety of production environments and different types of steel profile.

3. Automated access

The Roll Out Cantilever Rack with auxiliary equipment such as lifting can realize the automatic access and handling of steel profile, which greatly improves the work efficiency and safety. Automation reduces manual intervention and reduces operational risk.

Efficiency indicators of Motorized Roll Out Cantilever Racks:

• Storage capacity: 60%

• Productivity: 59%

• Space utilization: 72%

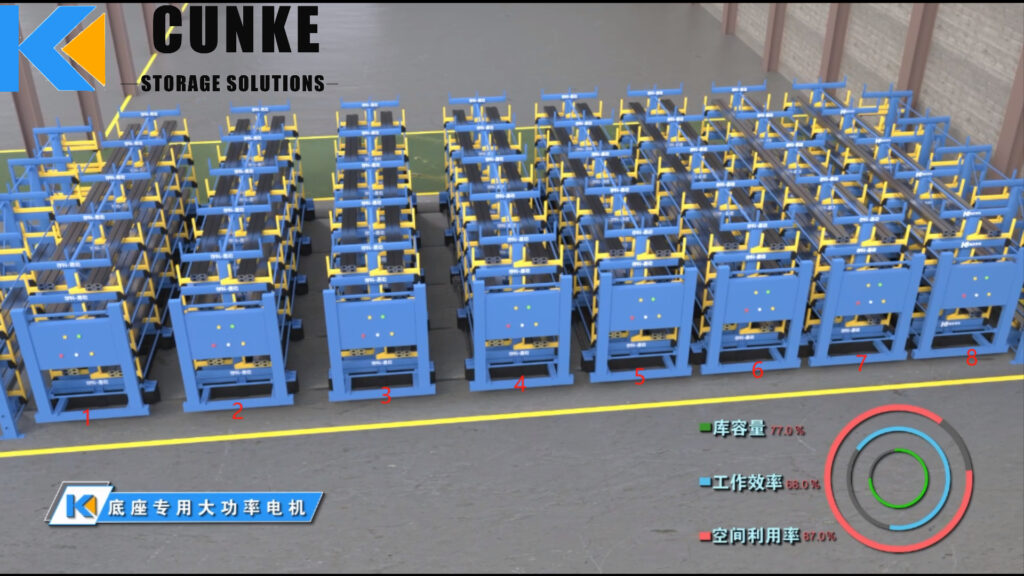

Innovation of Electrically Moving Roll Out Cantilever Rack

On the basis of the Motorized Roll Out Cantilever Racks, the Electrically moving roll out cantilever racks came into being. This kind of rack not only has all the advantages of the Roll Out Cantilever Rack, but also further improves the space utilization and access efficiency by increasing the mobility function. The overall Electrically moving roll out cantilever rack can be moved left and right, the utilization rate of space has increased by 30%. For the same area, four groups of roll out cantilever racks and three channels were needed before, but now we can make five groups of roll out cantilever racks, only one channel is reserved, and the warehouse capacity is greatly increased.

1. Efficient space utilization

Through its unique mobile function, the Electrically moving roll out cantilever rack can realize the dense storage of multiple groups of racks without increasing the number of channels. This design greatly reduces the waste of space, improves the overall space utilization of the warehouse, and enables the limited site to store more steel profile.

• Multiple groups of racks intensive storage: Electrically moving roll out cantilever racks can be moved left and right, no matter how many groups of storage racks, only one channel can be accessed.

• Reduced space waste: This design greatly reduces the waste of space, improves the overall space utilization of the warehouse, and enables more steel profile to be stored on a limited site.

2. Flexible layout adjustment

The mobile function of the racks allows the layout of the warehouse to be flexibly adjusted according to production needs and market changes. Whether it is increasing or reducing the number of racks, or changing the size of the storage area, it can be easily achieved, providing great convenience for the operation and management of enterprises.

• Flexible adjustment of the number of racks: The movement of racks allows the layout of the warehouse to be flexibly adjusted according to production needs and market changes.

• Adapt to market changes: whether it is increasing or reducing the number of racks, or changing the size of storage areas, it can be easily achieved, providing great convenience for the operation and management of enterprises.

3. Efficient access

The roll out cantilever design of the rack, coupled with the electric move, makes access to the steel profile easy and fast. Workers do not need to find the required materials in the mountains of steel profile, just through the operation console, it is easy to automate the access and handling of steel profile.

• Automatic access: Automatic access and handling of steel profile can be easily achieved through the operation console, greatly improving work efficiency.

•Reduced human intervention: Automation reduces human intervention and reduces operational risk.

4. Stable load-bearing capacity and safety

The Electrically moving roll out cantilever rack adopts high-strength materials and precision manufacturing process to ensure the load-bearing capacity and stability of the rack. At the same time, the rack is also equipped with multiple safety protection devices, such as overload alarm, limit switch, etc., to ensure the safety of the access process.

• High-strength materials and precision manufacturing: The use of high-strength materials and precision manufacturing processes to ensure the load-bearing capacity and stability of the rack.

• Safety protection device: equipped with multiple safety protection devices, such as overload alarm, limit switch, etc., to ensure the safety of the access process.

Efficiency indicators of Electrically moving roll out cantilever racks:

• Storage capacity: 77%

• Productivity: 68%

• Space utilization: 87%

Future development trend

With the continuous advancement of industrial automation and intelligence, steel profile storage equipment and methods will continue to evolve. The future steel profile storage system will be more intelligent, efficient and environmentally friendly, mainly reflected in the following aspects:

1. Higher level of intelligence

The future steel profile storage system will make extensive use of artificial intelligence and Internet of Things technology to achieve more intelligent management. Through real-time data analysis and forecasting, you can more accurately grasp the inventory situation and production needs, optimize storage and production processes.

• Artificial Intelligence: Through artificial intelligence technology, automated management of steel profile storage can be achieved, including inventory monitoring, demand forecasting and production scheduling.

• Internet of Things: Through the Internet of Things technology, real-time monitoring and remote management of steel profile storage systems can be achieved to improve management efficiency and accuracy.

2. Customized solutions

According to the special needs of different industries and enterprises, steel profile storage systems will provide more customized solutions. Whether it is special specifications of steel profile storage, or complex warehouse layout, it can be met by custom design.

• Special specification storage: Provide customized storage solutions for different specifications of steel profile to ensure efficient and safe storage.

• Complex layout: According to the actual situation of the warehouse, provide optimized layout design to improve space utilization and operation efficiency.

3. Environmental protection and sustainable development

Future steel profile storage systems will be designed and manufactured with a greater focus on environmental protection and sustainability. Adopt more environmentally friendly materials and processes, reduce energy consumption and environmental impact, and contribute to the green development of enterprises.

• Environmentally friendly materials: Use environmentally friendly materials to reduce the impact on the environment.

• Sustainable processes: Use sustainable production processes to reduce energy consumption and carbon emissions.

Summary

From the ground pile mode to the Electrically moving roll out cantilever rack, the storage method of steel profile has undergone significant changes. Each storage method has its specific application and advantages and disadvantages, but with the development of science and technology and changes in industrial demand, Electrically moving roll out cantilever rack is undoubtedly the most advanced and efficient storage solution. It not only improves the space utilization and access efficiency, but also realizes a higher level of operation management through the intelligent management system.

In the future, with the further development of industrial automation and intelligence, Electrically moving roll out cantilever racks will be applied in more industries to help enterprises achieve more efficient and safer production management. If you have any needs or questions, please feel free to contact us. We will be happy to help you find the most suitable steel profile storage solution.