Revolutionizing Long Material Storage with Intelligent Automation

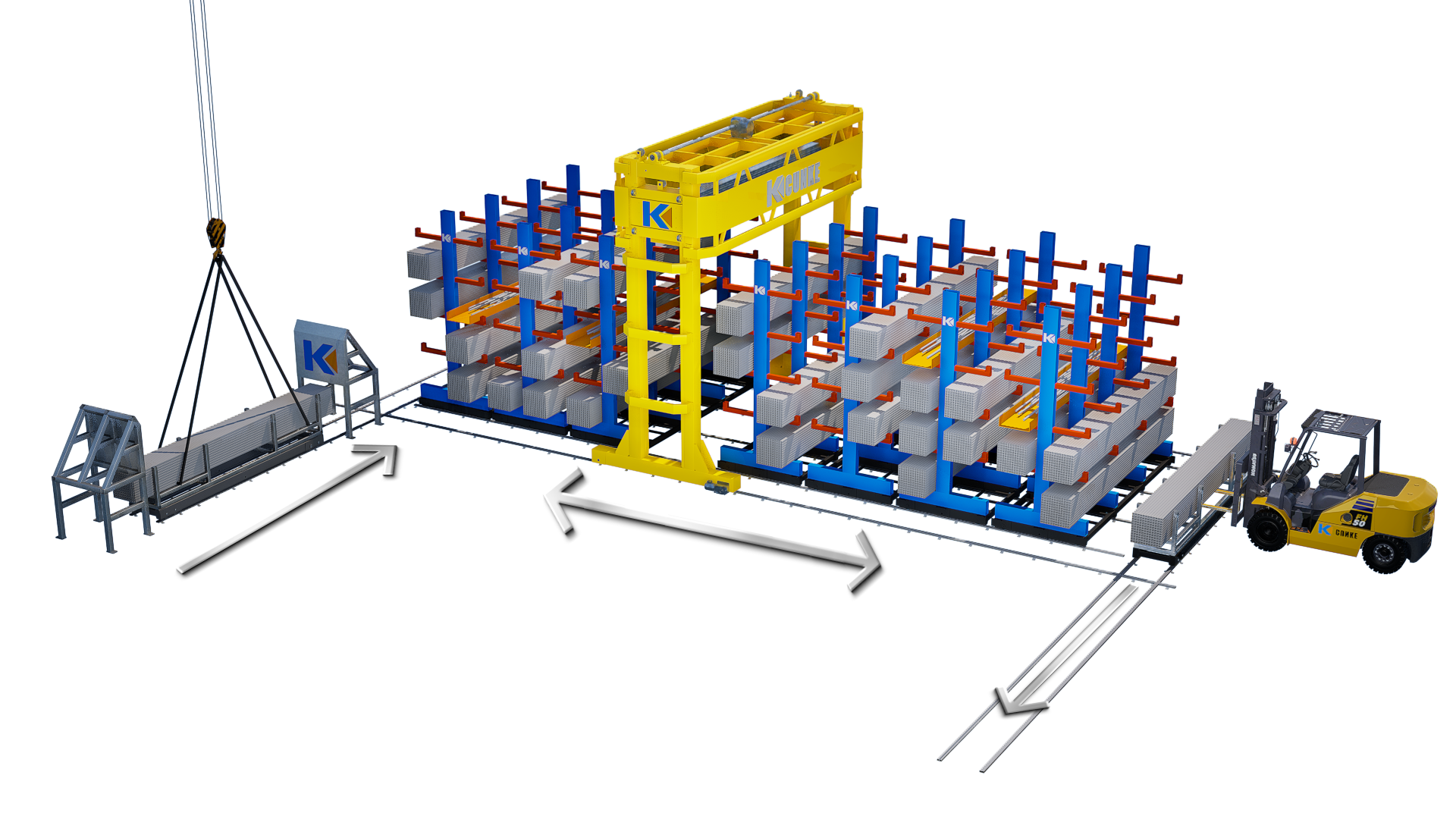

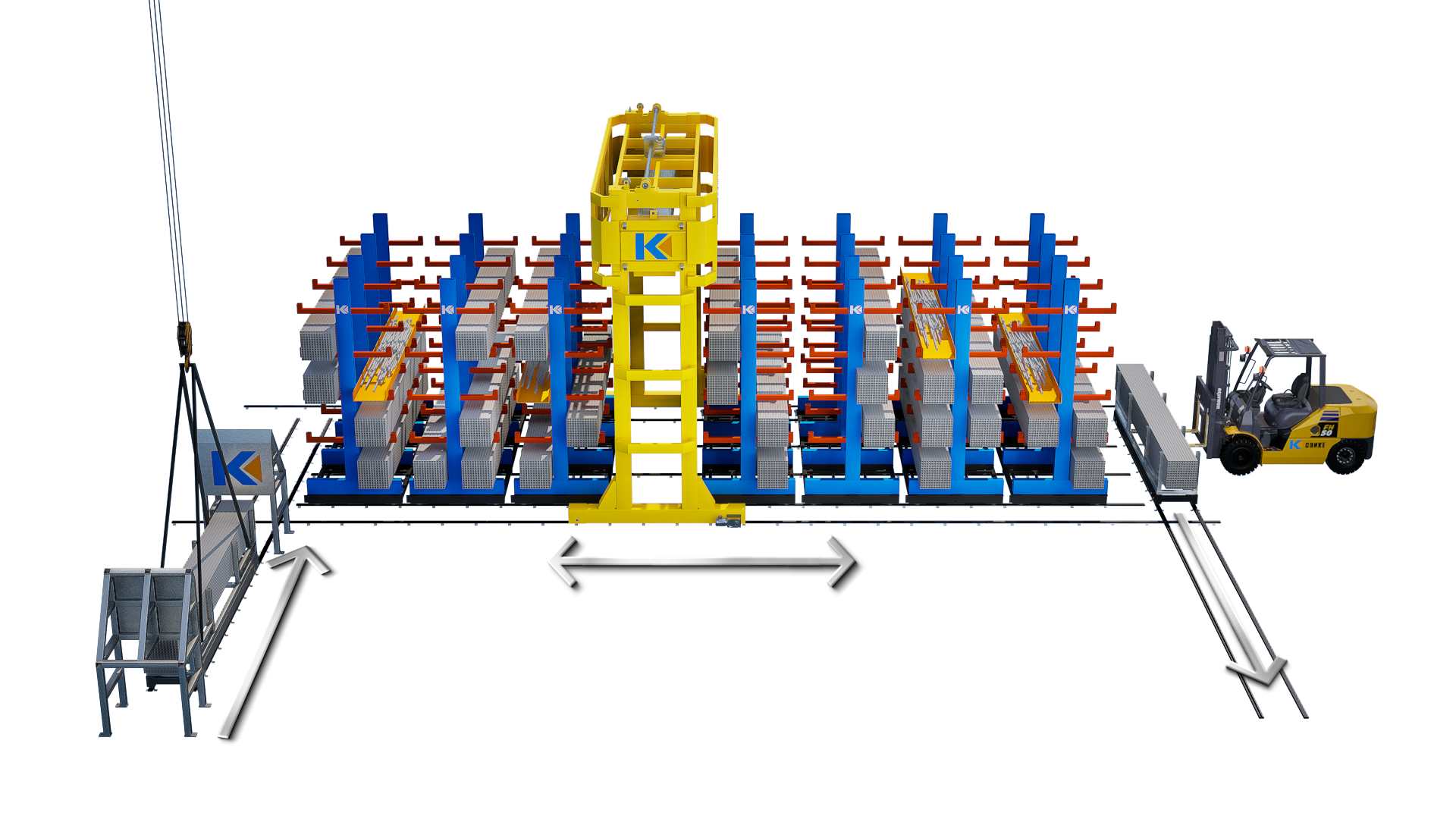

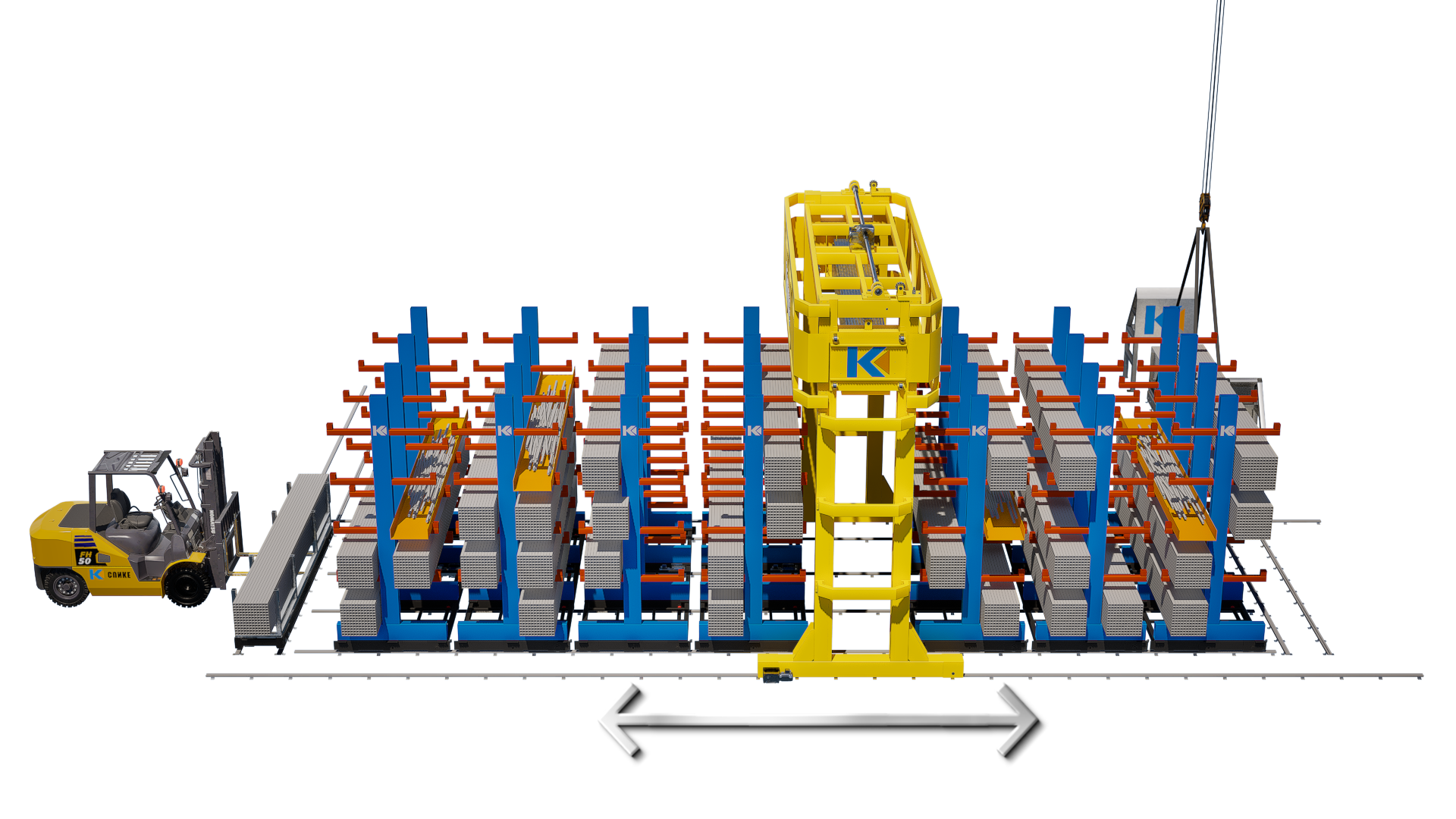

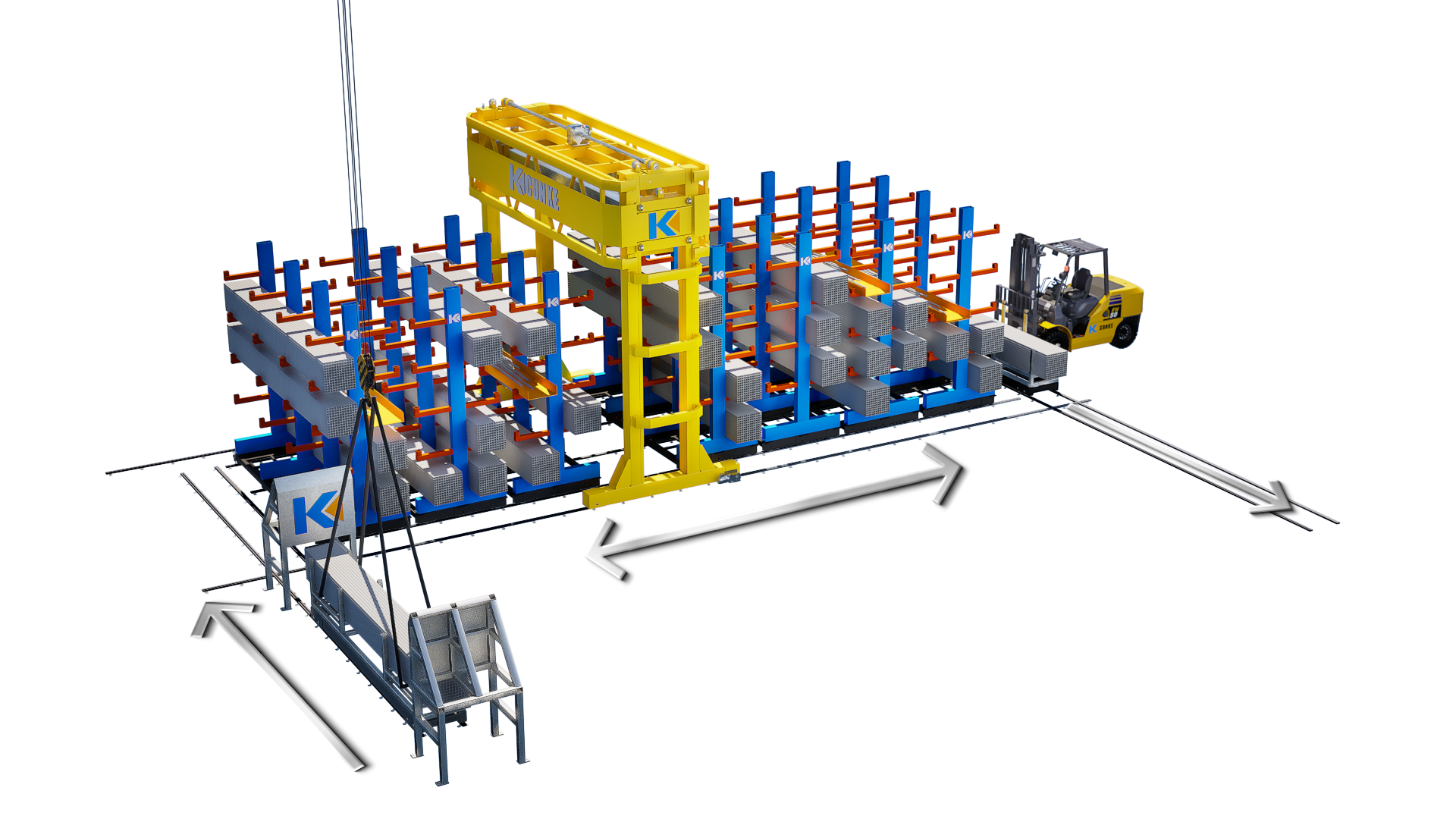

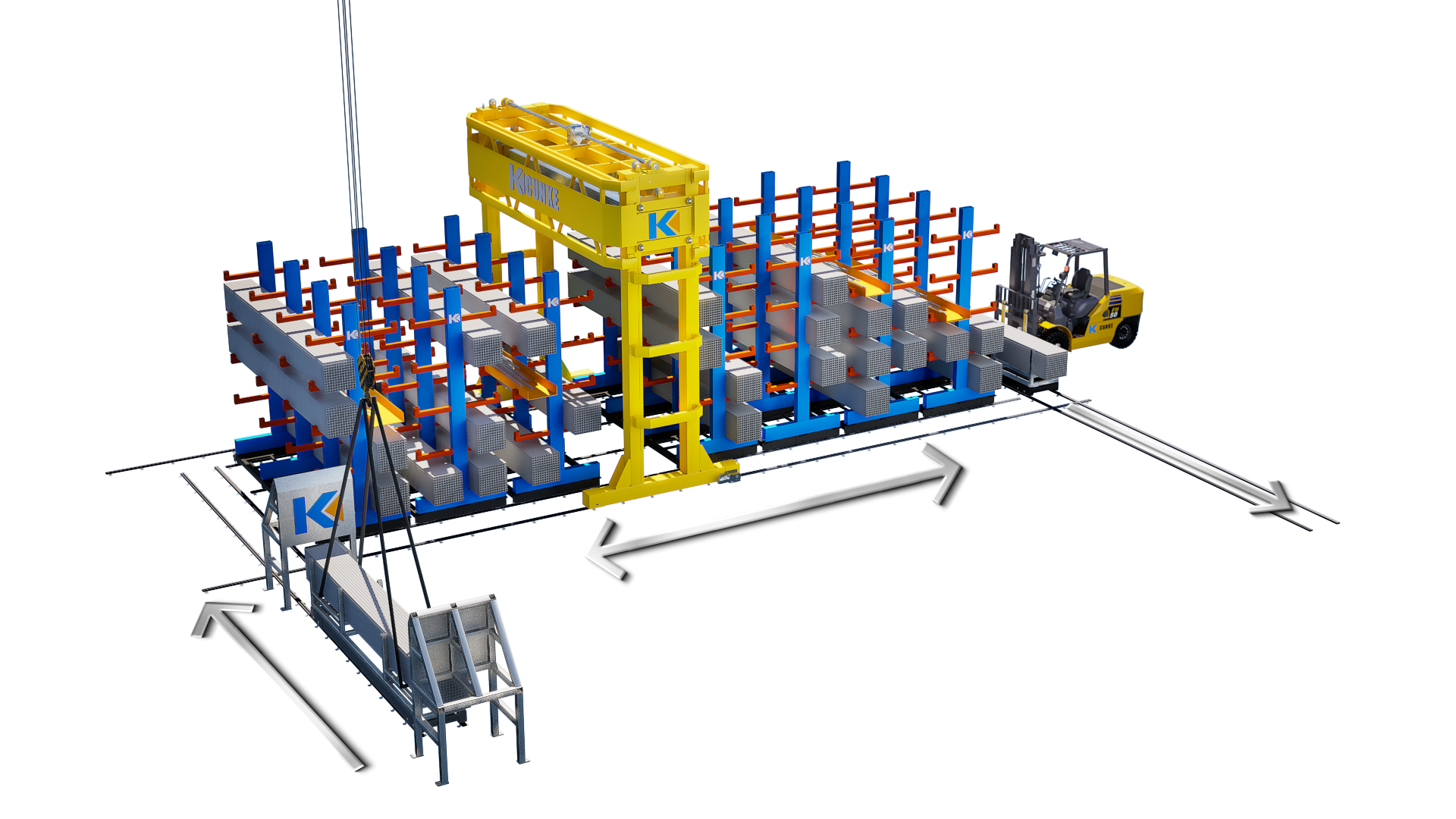

The Automated Profile Storage System is a state-of-the-art storage solution purpose-built for managing long metal profiles—such as aluminum, steel, and copper extrusions—more safely, efficiently, and compactly than traditional storage methods. This system seamlessly integrates gantry crane automation, motorized mobile racking, and intelligent dispatch controls to optimize every square meter of your warehouse.

| Key Specifications | |

| Max profile length | 6 meters |

| Load per slot | Up to 3 tons |

| System height | Customizable up to 8 meters |

| Rack structure | Modular and expandable |

| Installation time | Approx. 8–12 weeks from design to handover |

Traditional profile storage systems suffer from several chronic inefficiencies:

The Automated Profile Storage System solves these problems with an integrated, smart, and space-saving design that enables zero-aisle, high-density, and high-speed operations.

The heart of the system is a precision-controlled gantry crane working in tandem with electric mobile racking, enabling completely automated material storage and retrieval without forklift intervention.

The system transforms underutilized warehouses into high-density storage hubs.

What used to take 20–30 minutes now takes just 3–5.

A centralized control platform powers the entire operation:

Manual errors and high-level operations are minimized or eliminated.

In a standard 300 m² facility, most customers:

A leading aluminum profile company cut picking times from 25 minutes to 4 minutes, eliminated forklift accidents, and achieved a 22% increase in storage capacity—all in a smaller footprint.

Another automotive components firm reduced profile damage by 95% and lifted order fulfillment accuracy to 99.8%.

This system is ideal for:

Whether you’re storing aluminum extrusions, copper busbars, or structural steel profiles, the Automated Profile Storage System delivers a smart, scalable solution.