Every industrial facility has one thing in common — limited space and endless materials. If your production line handles sheet metal, steel profiles, or other heavy components every day, you know how quickly clutter builds up.

Choosing the right industrial storage system isn’t just about stacking materials neatly. It’s about improving workflow efficiency, safety, and space utilization. Yet, many clients come to us unsure what kind of system truly fits their operation. They often ask us to introduce every model we have — which can be overwhelming and time-consuming for both sides.

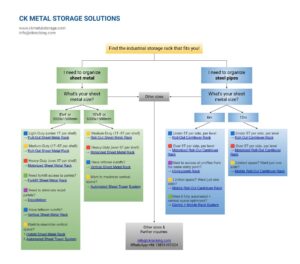

To make it easier, we’ve created this practical guide. By following these three key steps, you’ll be able to identify your needs clearly and select the storage system that actually solves your bottleneck — not just one that looks good on paper.

Step 1: Identify What You Need to Store

The first and most important question is what kind of material are you handling?

Different materials require completely different storage structures and loading methods.

- Sheet Metal Storage

Sheet metal is flat and heavy. It’s often used in fabrication workshops, laser cutting plants, and metal processing factories. Standard sheet sizes include 8’x4′ (3000x1500mm) and 10’x5′ (6000x1500mm), but many workshops also handle custom dimensions.

For sheet metal, the focus is on easy access, protection from scratches, and efficient stacking to keep selectivity. That’s where roll-out sheet metal racks and motorized roll out sheet metal rack systems shine — they let you pull out each shelf to access materials safely, without unstacking piles.

- Steel Profiles, Pipes, and Bars

If you work with long materials like pipes, tubes, angles, or flat bars, you’re dealing with an entirely different challenge. These materials often measure 6m or 12m in length.

For this category, roll out cantilever racking systems are the best solution. They support long materials on horizontal arms extending from a central column, allowing cranes to access the load easily.

Once you know what type of material dominates your workflow — sheet metal or steel profiles — you’re ready for the next step.

Step 2: Identify the Size and Weight of Your Material

Not all sheet metals or profiles are equal. Some are light aluminum sheets, others are thick steel plates or heavy-duty pipes. Your storage choice must depend on load capacity and handling frequency.

Here’s how to break it down:

For Sheet Metal

| Load Capacity | Recommended System | Ideal For |

| Under 1 ton per shelf | Pull-Out Sheet Metal Rack | Small workshops or light-duty operations. |

| 1–5 tons per shelf | Roll-Out Sheet Metal Rack | Medium-duty use; most popular option for daily fabrication. |

| Over 5 tons per shelf | Motorized Sheet Metal Rack | Heavy-duty production lines requiring frequent access. |

If you want to go beyond simple loading and storage, there are several specialized systems worth considering:

- Forklift Sheet Metal Rack – For material stored on pallets that need forklift access.

- Depalletizer – If you want to eliminate wooden pallets and go for a more efficient, metal-only workflow.

- Vertical Sheet Metal Rack – Perfect for storing leftover cutoffs or smaller pieces upright.

- Automated Sheet Tower System – Uses vertical stacking and automation to maximize floor space and speed up retrieval.

For Steel Profiles and Pipes

| Load Capacity | Recommended System | Ideal For |

| Under 5 tons per side | Roll-Out Cantilever Rack | Manual or semi-manual operations with frequent loading/unloading. |

| Over 5 tons per side | Motorized Roll-Out Cantilever Rack | Heavy-duty storage where safety and speed matter. |

| Limited floor space | Mobile Roll-Out Cantilever Rack | Single-aisle design to save every inch of workshop space. |

| One-side access for all materials | Honeycomb Rack | Allows all profiles to be accessed from a single entry point. |

| Automated high-density storage | Gantry + Mobile Rack System | Fully automated, ideal for large-scale production with continuous flow. |

Understanding the weight and dimensions of your materials helps ensure your rack system won’t just look organized — it will also be safe, durable, and easy to use.

Why the Right Storage System Matters

An efficient industrial storage system isn’t just about neatness — it’s a productivity tool. The right setup can:

- Reduce material handling time by up to 90%

- Lower the risk of damage and accidents

- Improve space utilization dramatically

- Enhance workflow efficiency and machine feeding speed

- Boost overall production consistency

For example, a roll-out system allows operators to slide out entire layers of sheets or profiles, access the desired material, and slide it back in — all within seconds. No more unstacking or waiting for forklifts to move piles around.

Motorized and automated systems take it one step further, integrating with production planning or laser cutting schedules to deliver materials exactly when needed.

This isn’t just storage — it’s smart material management.

Key Takeaway: Match Your System to Your Reality

Don’t choose a storage system based only on its technical specs. The best rack for you is the one that fits your specific workflow, space, and materials.

Here’s a quick recap:

- Identify your material type – sheet metal or steel profiles.

- Measure your material size and weight – know your average load per shelf or per side.

- Choose based on your bottleneck – whether that’s manual handling, wasted space, or damaged materials.

With this process, you can confidently find the right industrial storage rack that supports your daily operations instead of slowing them down.

Work Smarter with CK Metal Storage

At CK Metal Storage Solutions, we specialize in helping manufacturers transform disorganized workshops into efficient, high-performing spaces. Our roll-out, motorized, and automated storage systems are designed to fit your production flow, safety requirements, and future scalability.

Whether you’re handling tons of sheet metal or managing thousands of steel profiles, our team can help you pinpoint the system that truly matches your needs — not just the one that’s easiest to sell.

📧 info@ckracking.com

🌐 www.ckmetalstorage.com

Upgrade your storage.

Simplify your workflow.

Build a safer, smarter, and more productive workshop — one rack at a time.