In warehouses that handle long materials, honeycomb racks are often used as the main storage structure. After a period of use, many operators notice that the space above these racks is largely unused. A top platform is usually introduced at this stage, not as a cosmetic upgrade, but as a practical way to gain additional storage space without expanding the building.

This article explains what the top platform of a honeycomb rack is, how it is designed, and how it is typically used in real warehouse environments.

What Is a Honeycomb Rack?

A honeycomb rack is a storage system mainly used for long materials such as steel profiles, aluminum extrusions, pipes, and tubes. The rack is divided into vertical cells, which makes it easier to separate different lengths or types of material and access them using a crane or forklift.

You will often find honeycomb racks in metal processing plants, fabrication workshops, and warehouses where long materials need to be stored safely but still remain easy to handle.

What Is the Top Platform of a Honeycomb Rack?

The top platform is a load-bearing level installed above the honeycomb rack structure. In simple terms, it turns the empty space above long-material storage into usable storage or working space.

Functionally, it is similar to a mezzanine floor, but instead of being an independent structure, it is designed together with the rack below. Long materials remain stored in the honeycomb rack at ground level, while the platform above is used for pallets, cartons, bundled profiles, or other goods.

Main Components of the Top Platform

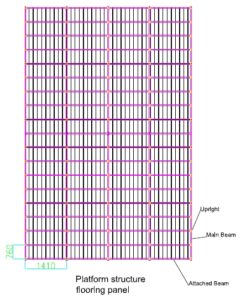

Although designs vary from project to project, a typical honeycomb rack top platform usually includes:

- Load-bearing steel beams that transfer weight to the rack columns or uprights

- Steel flooring panels forming the storage and walking surface

- Handrails along open edges for fall protection

- A staircase for safe personnel access

- An optional loading gate when goods are handled by forklift or crane

These elements are standard, but their size and arrangement are adjusted according to the warehouse layout and usage requirements.

Loading Capacity and Design Considerations

In most projects, the top platform is designed for a load capacity between 500 and 2000 kg per square meter. The required capacity depends on what will be stored and how often the platform will be accessed.

Higher load ratings mean heavier beams and more steel, which directly affects cost. For this reason, designers usually focus on the actual storage scenario rather than simply selecting the maximum possible capacity. A well-balanced design provides sufficient safety while avoiding unnecessary overengineering.

What Can Be Stored on the Platform?

One reason the top platform is popular is its flexibility. Because the surface is flat and stable, it can accommodate many different types of goods, for example:

- Long profiles, stored as full bundles or loose pieces

- Palletized materials

- Cartons, boxes, or packaged components

- Tools, spare parts, or auxiliary materials

As storage needs change, the same platform can often be reorganized without modifying the structure.

How Goods Are Placed on the Platform

There are two common ways goods are handled on a honeycomb rack top platform.

In facilities equipped with overhead cranes, materials can be lifted directly onto the platform from above. This is often preferred for long or heavy items.

In other warehouses, forklifts place pallets onto the platform through a loading gate. Once on the platform, the pallets are typically moved into position using a manual pallet jack. This method allows controlled movement while keeping operators safe.

Platform Floor Surface Options

The choice of floor surface depends largely on load type and operating conditions. Common options include:

- Pierced or perforated floors, usually for lighter loads and ventilation needs, but not suitable for manual pallet jacks

- Smooth steel floors, which are more versatile and support a wide range of handling requirements

- Smooth floors with checker plate, offering better slip resistance in industrial environments

- Smooth floors with partial perforation, often selected when fire sprinkler water needs to pass through the platform

A Note on Design Philosophy

Adding a top platform is not simply about placing a floor above a rack. Load capacity, handling method, safety features, and future adjustments all need to be considered together.

When these factors are aligned, the platform integrates naturally into daily operations and remains useful as storage demands evolve.

A honeycomb rack top platform is an effective way to make better use of warehouse height while keeping long materials and general cargo organized within the same area.

With proper design, it improves storage capacity and operational efficiency without compromising safety.

Call Now: ✆ +86 138 5149 1524

Email: info@ckracking.com