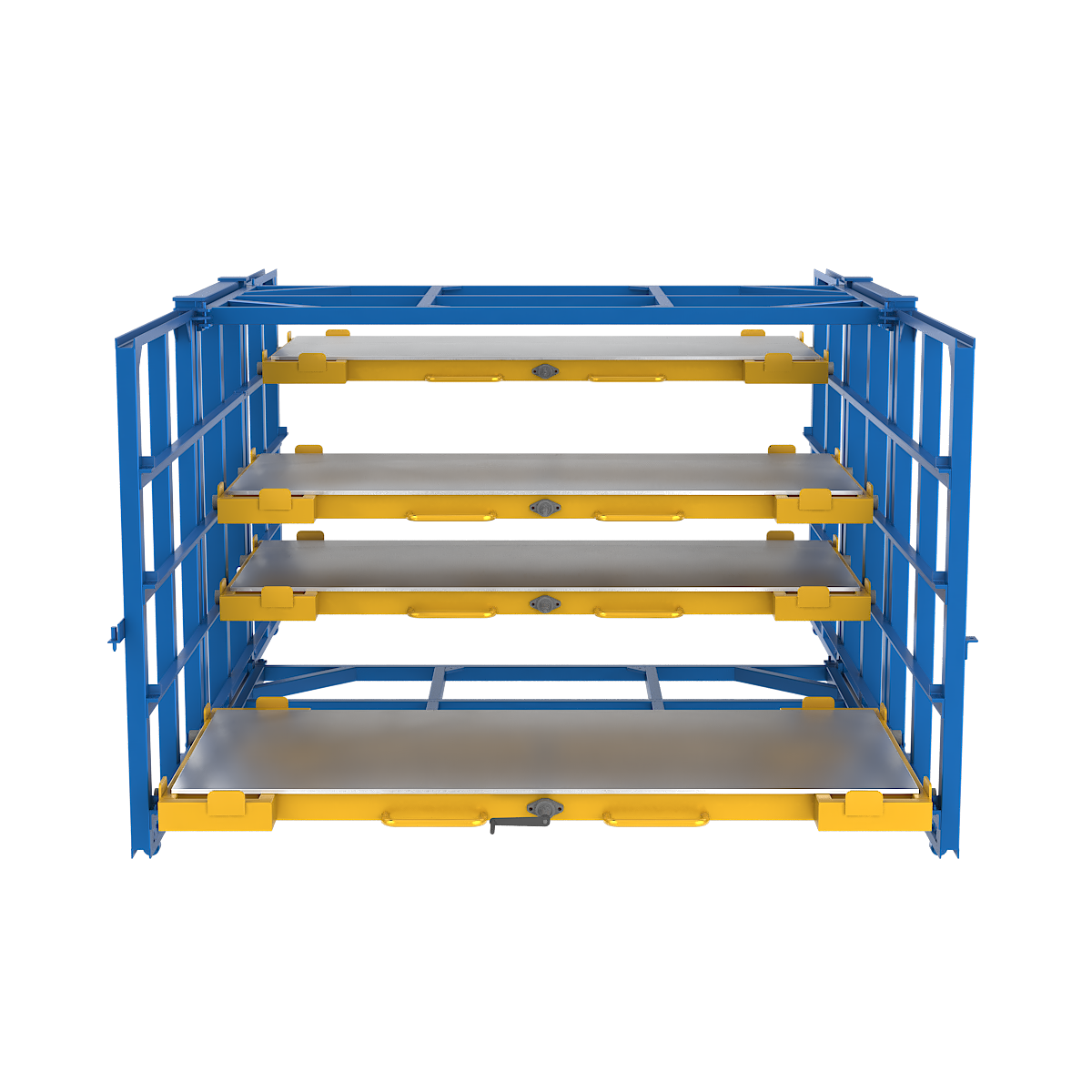

Elevate your workshop’s efficiency with our Double-Sided Sheet Metal Rack, designed to redefine storage and retrieval operations.

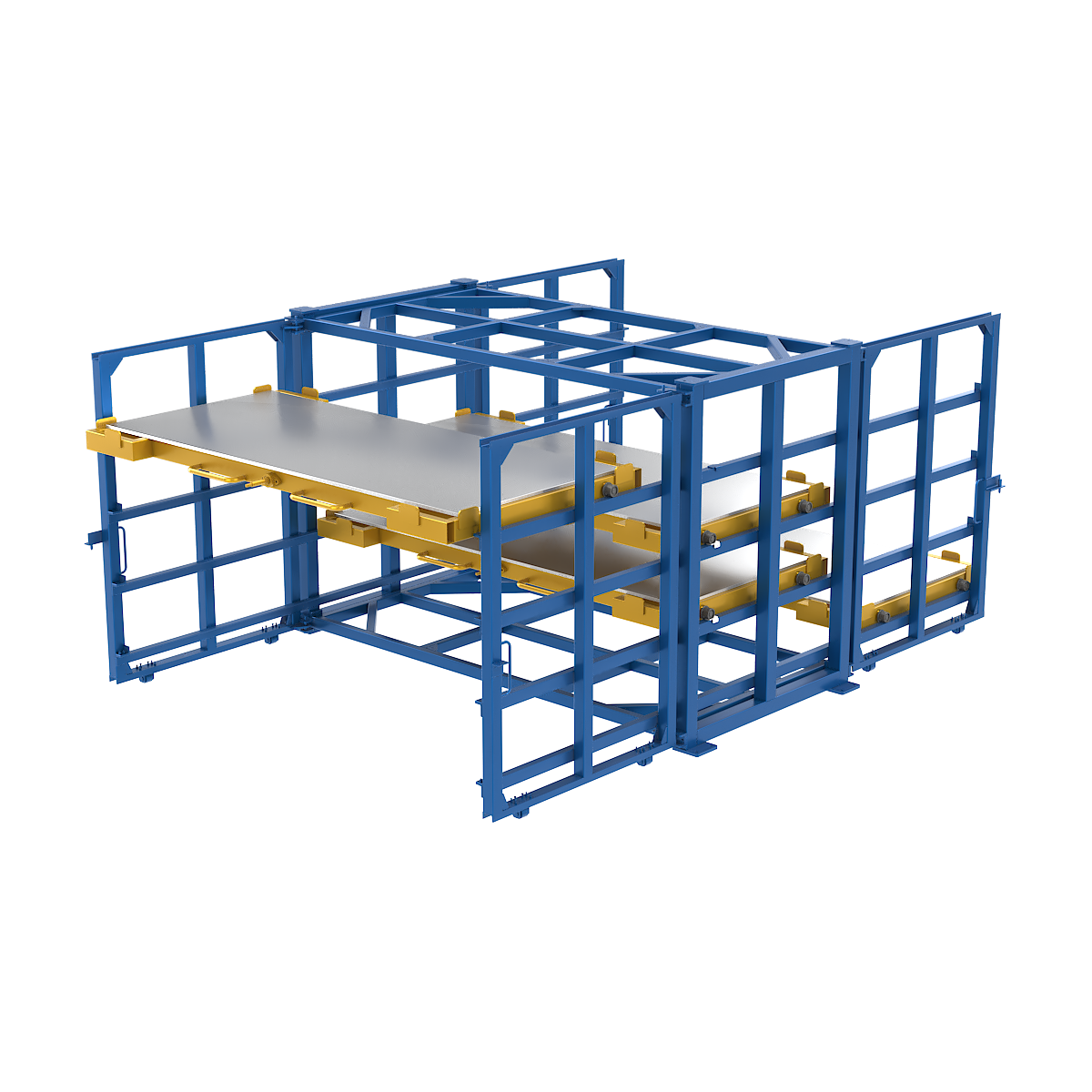

This cutting-edge solution boasts a double hinged frame, enabling simultaneous storage and access from both sides, dramatically increasing production efficiency and conserving time. Tailored for high-demand manufacturing and fabrication settings, it optimizes usable space and streamlines workflow. This rack not only accelerates material handling but also fosters a more orderly and productive environment.

Perfect for fast-paced operations where efficiency and space utilization are critical, it ensures essential materials are readily accessible. The Double-Sided Sheet Metal Rack is an essential upgrade for any facility focused on boosting productivity and simplifying material management processes.

| Technical Specifications | |

| Usable Length / Level | max. 6200 mm |

| Usable Depth / Level | max. 2500 mm |

| Usable Height / Level | min. 70 mm |

| Number of Levels | Normally 5 ~ 8 |

| Load Capacity / Level | max. 5000 kg |

Clients should consider a double-sided sheet metal rack in scenarios where efficiency and flexibility in the production line are paramount. This innovative rack design facilitates loading new materials from one side while allowing workers to access and pick up materials from the opposite side. The ability to load and unload from both sides not only enhances operational efficiency but also introduces greater flexibility to the production process. This setup is particularly beneficial for environments where rapid access to materials and smooth workflow are essential.

There are three methods for placing sheets onto the drawers, each accommodating different operational needs:

Forklift Use:

Skids can be added to the drawers to facilitate forklift operations, although this modification may reduce the available storage height.

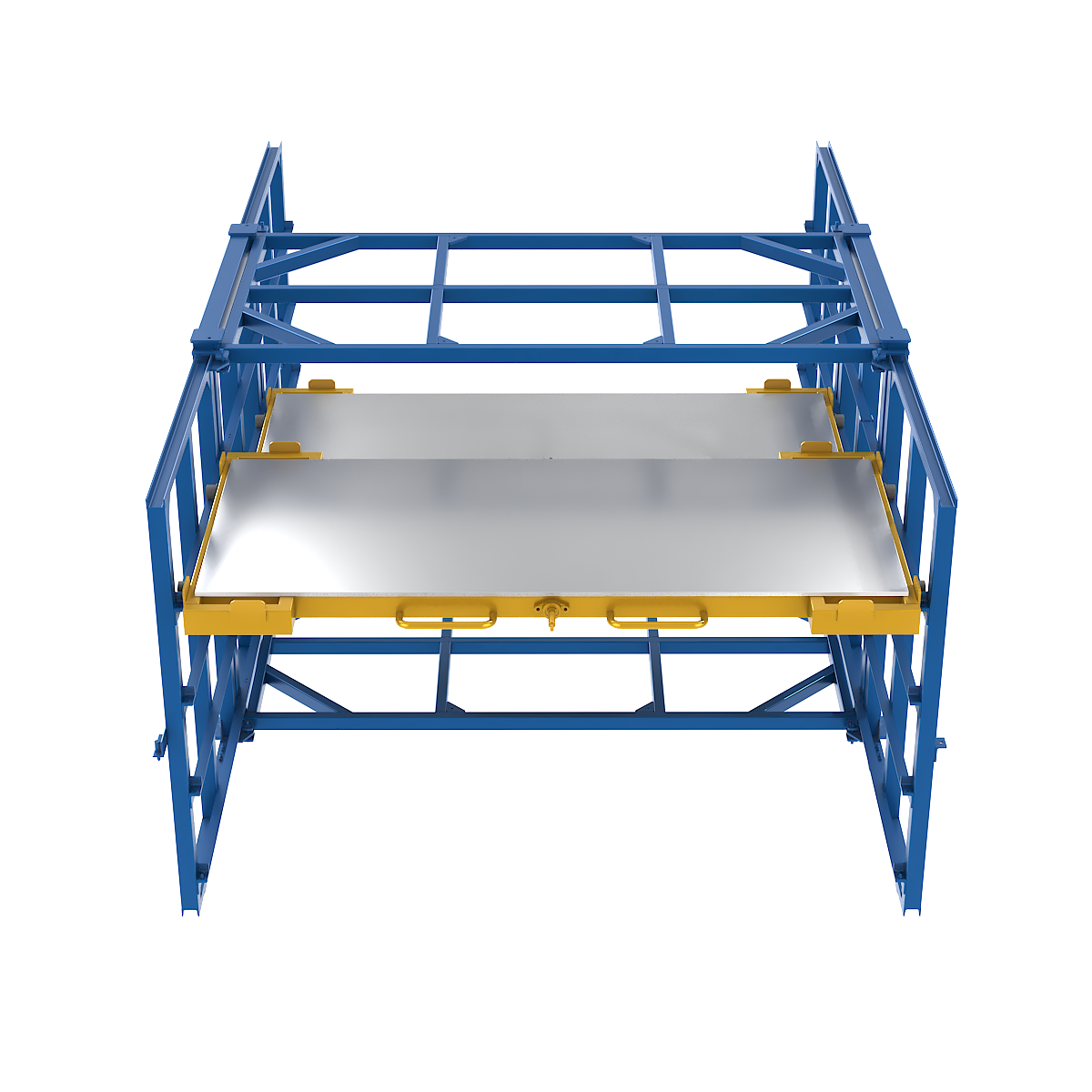

Crane with Hooks:

The drawers are designed with indents, making it easy to use hooks for sheet placement and removal.

Crane with Strips:

Similar to the forklift method, we can equip the drawers with skids designed for strip use, enhancing ease of sheet placement and removal. This option also impacts the storage height available.

These options ensure flexibility in how materials are handled and stored, optimizing workflow according to your facility’s equipment and space constraints.