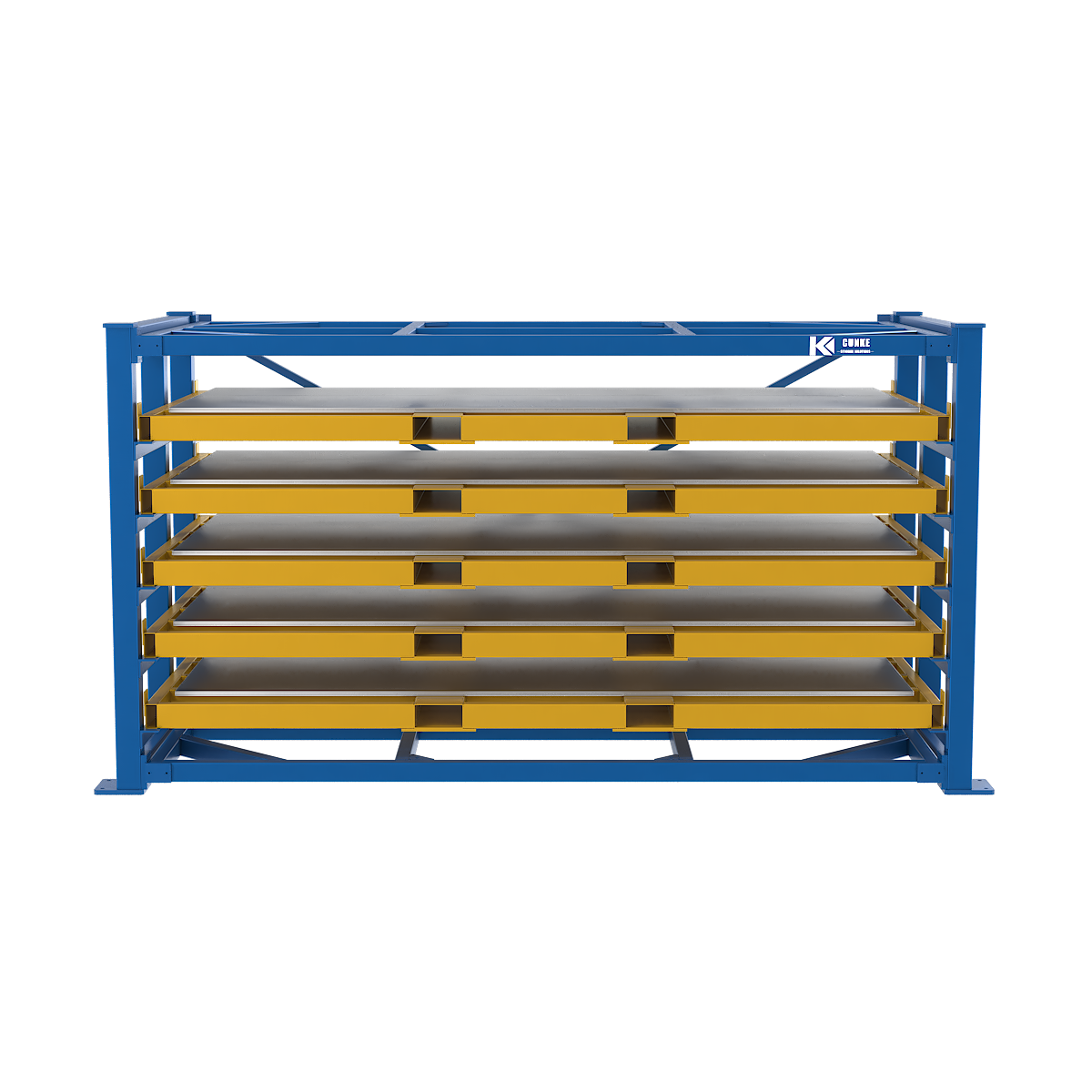

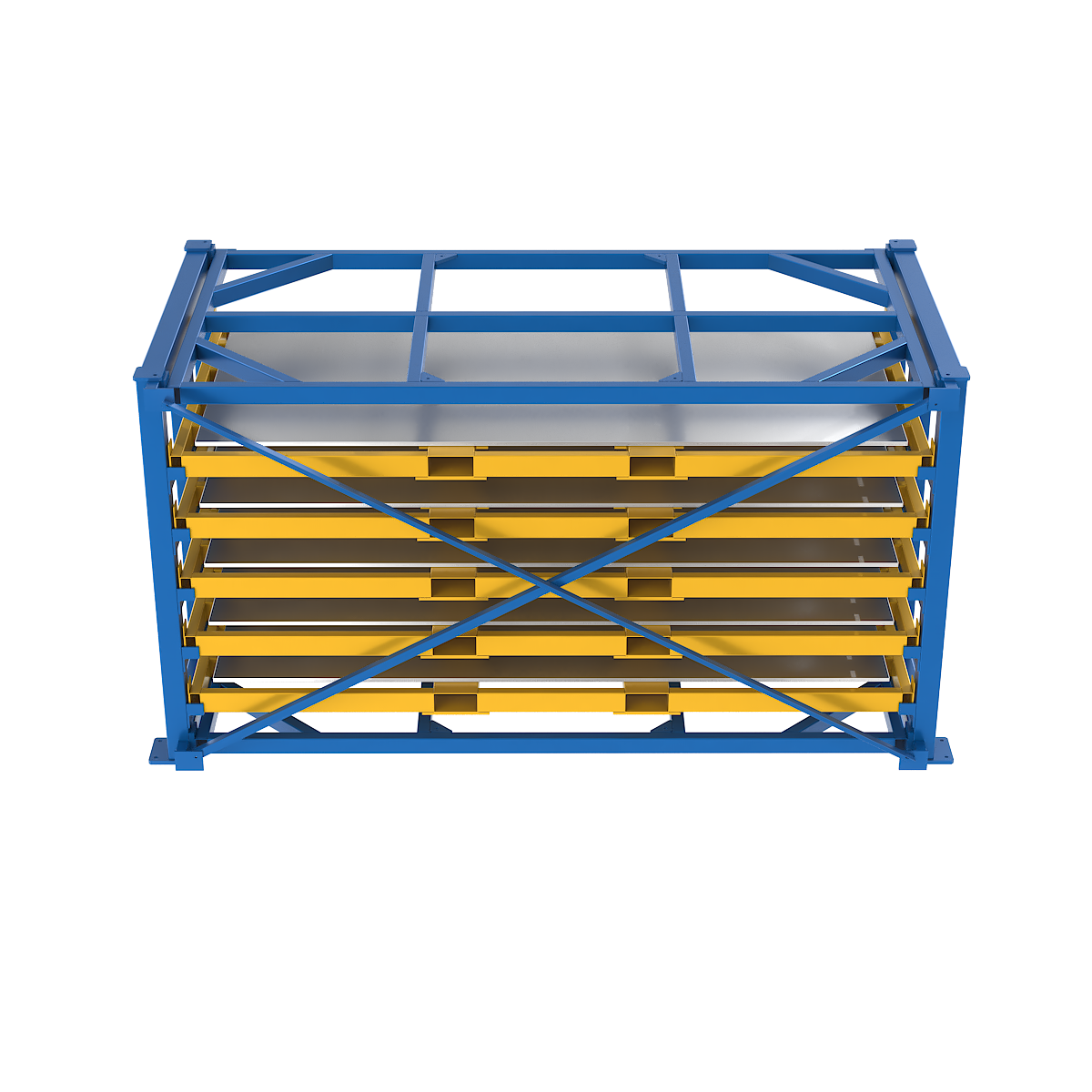

Streamlining sheet metal storage becomes crucial as laser and punching technologies advance, demanding efficient and space-saving solutions. Forklift Sheet Metal Rack offers an optimal material handling system, ensuring raw materials are readily accessible, secure, and well-protected.

Utilizing a manual cartridge approach, Forklift Sheet Metal Rack system liberates valuable floor space, boosts operational efficiency, enhances safety, and fosters a lean manufacturing environment. Embrace the future of streamlined storage and elevate your facility’s productivity and safety standards with our cutting-edge solution.

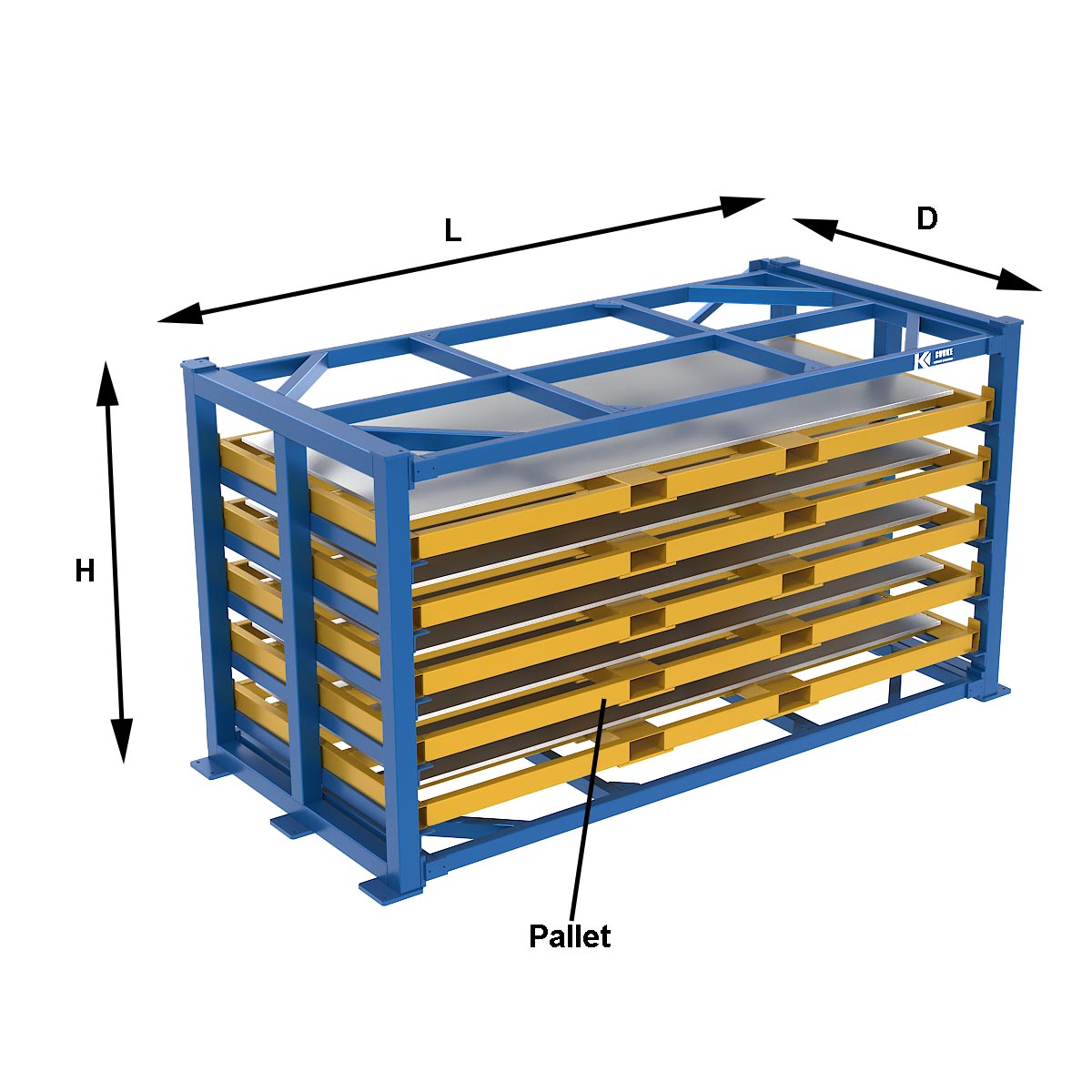

| Technical Specifications | |

| Usable Length / Level | max. 6200 mm |

| Usable Depth / Level | max. 2500 mm |

| Usable Height / Level | min. 70 mm |

| Number of Levels | max. 15 |

| Load Capacity / Level | max. 3000 kg |

Forklift sheet metal racks are typically utilized in raw material warehouses. They offer the advantage of bulk storage while maintaining selectivity. However, access and transport exclusively require a forklift.

On the other hand, roll out sheet metal racks are commonly positioned adjacent to laser cutting machines. They facilitate the individual selection and transfer of sheets directly to the laser cutting machine, allowing for piece-by-piece handling.

This distinction should guide you in choosing the appropriate rack type based on your operational needs and the layout of your facility.

Absolutely. Both the storage height of each level and the dimensions of the steel pallets can be fully customized according to the client’s specifications. When planning for adjustments or custom configurations, clients should consider the maximum lifting height and maximum lifting capacity of their forklifts. This ensures the rack setup is perfectly tailored to match their operational needs and equipment capabilities.