Maximize Steel Profile and Pipe Storage with Safety, Space Efficiency, and Ergonomic Access

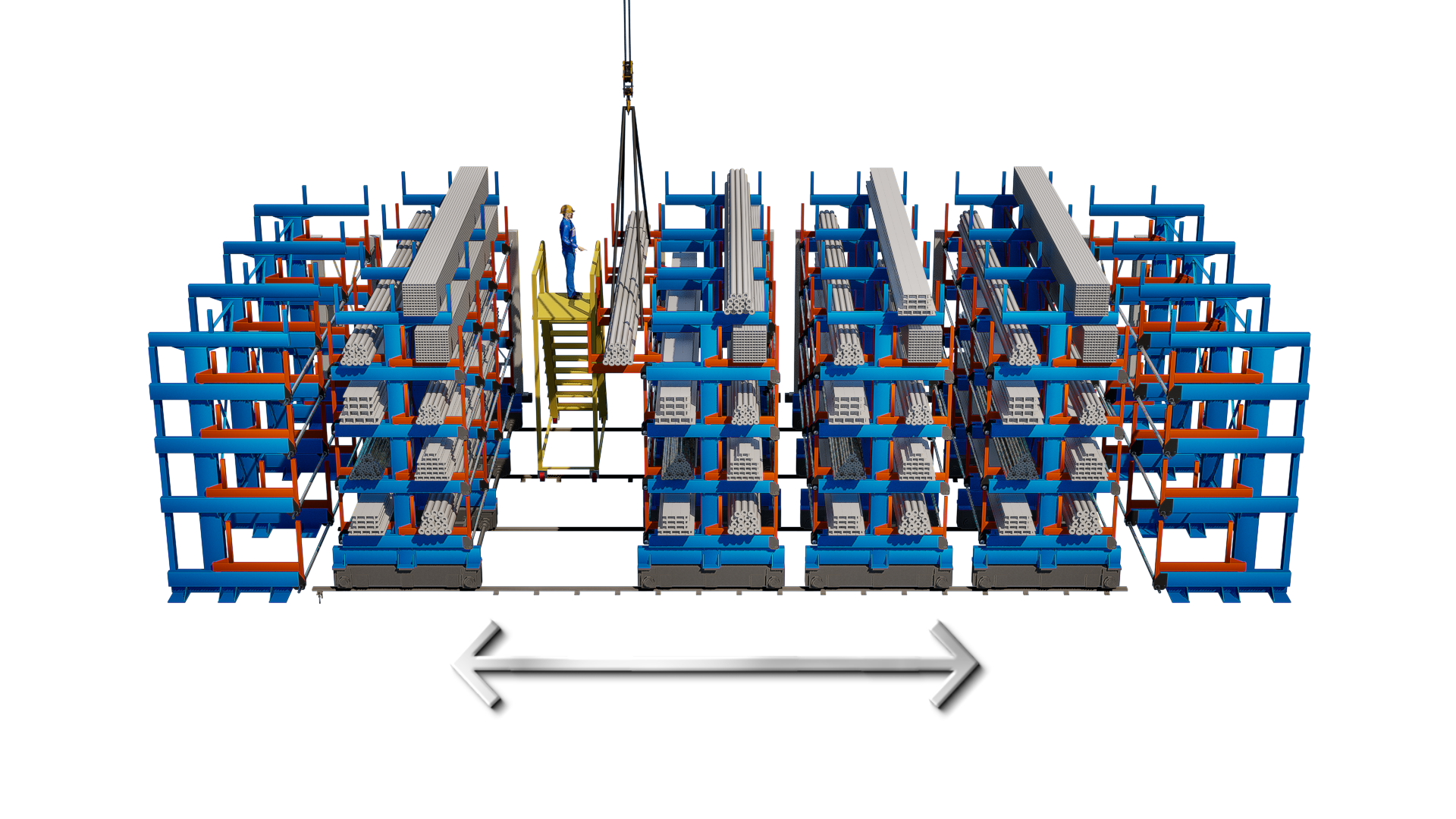

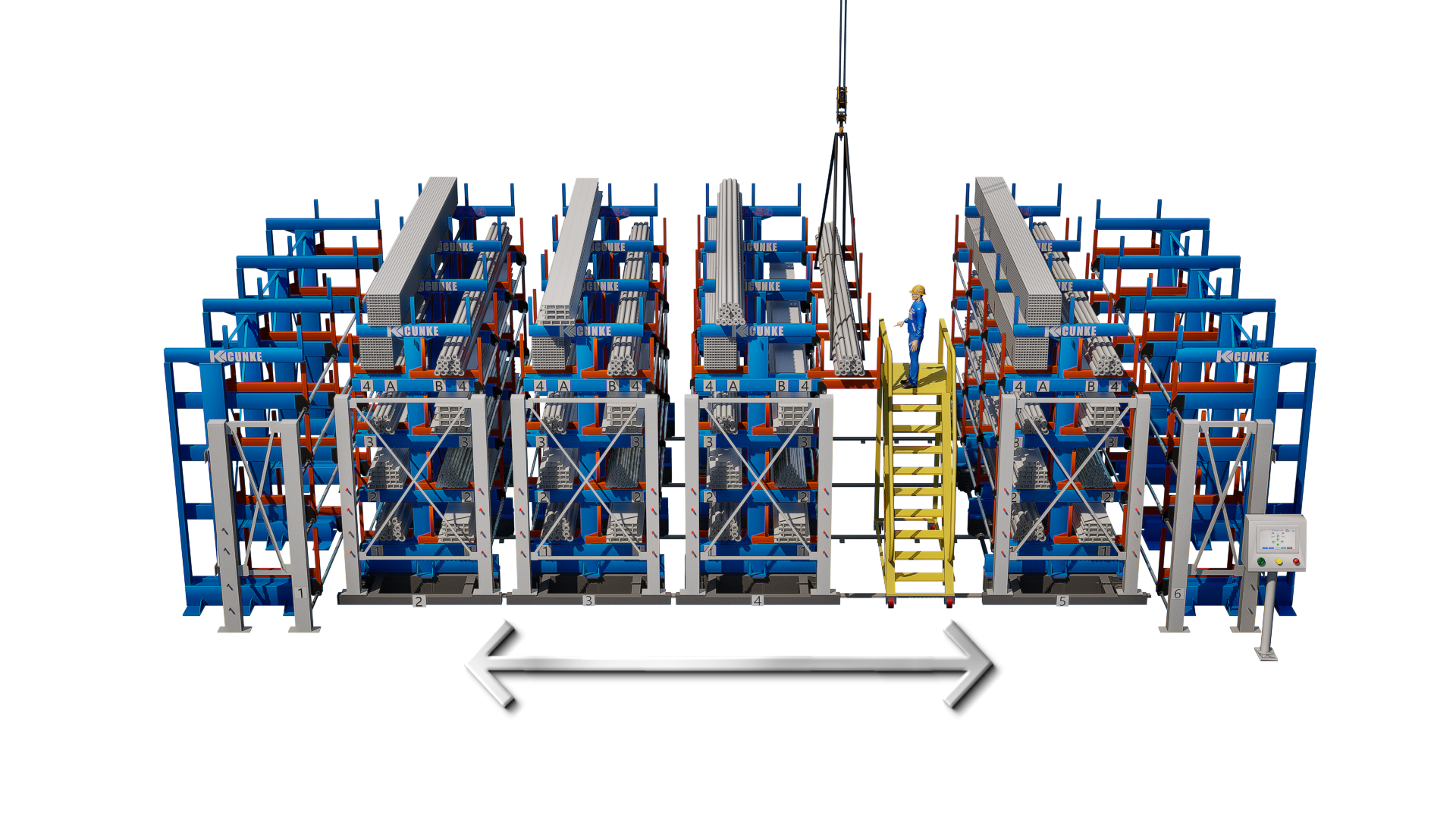

The Mobile Roll-Out Cantilever Rack is an advanced material storage solution designed to optimize space usage, simplify long material handling, and dramatically improve safety and workflow in industrial environments. Powered by a mobile base system and integrated with roll-out cantilever arms, this rack system eliminates the need for wide aisles and difficult-to-reach storage positions.

Built for storing steel profiles, aluminum extrusions, copper tubes, bars, and other long materials, this rack system is ideal for factories, warehouses, and fabrication shops where overhead cranes are available and floor space is limited.

Unlike traditional fixed cantilever racking, this mobile solution uses powered mobile bases that slide along embedded floor tracks. When material access is required, the selected rack row is rolled out, providing full ergonomic access to every level. There’s no need for forklifts to drive into tight aisles or for workers to climb or reach dangerously.

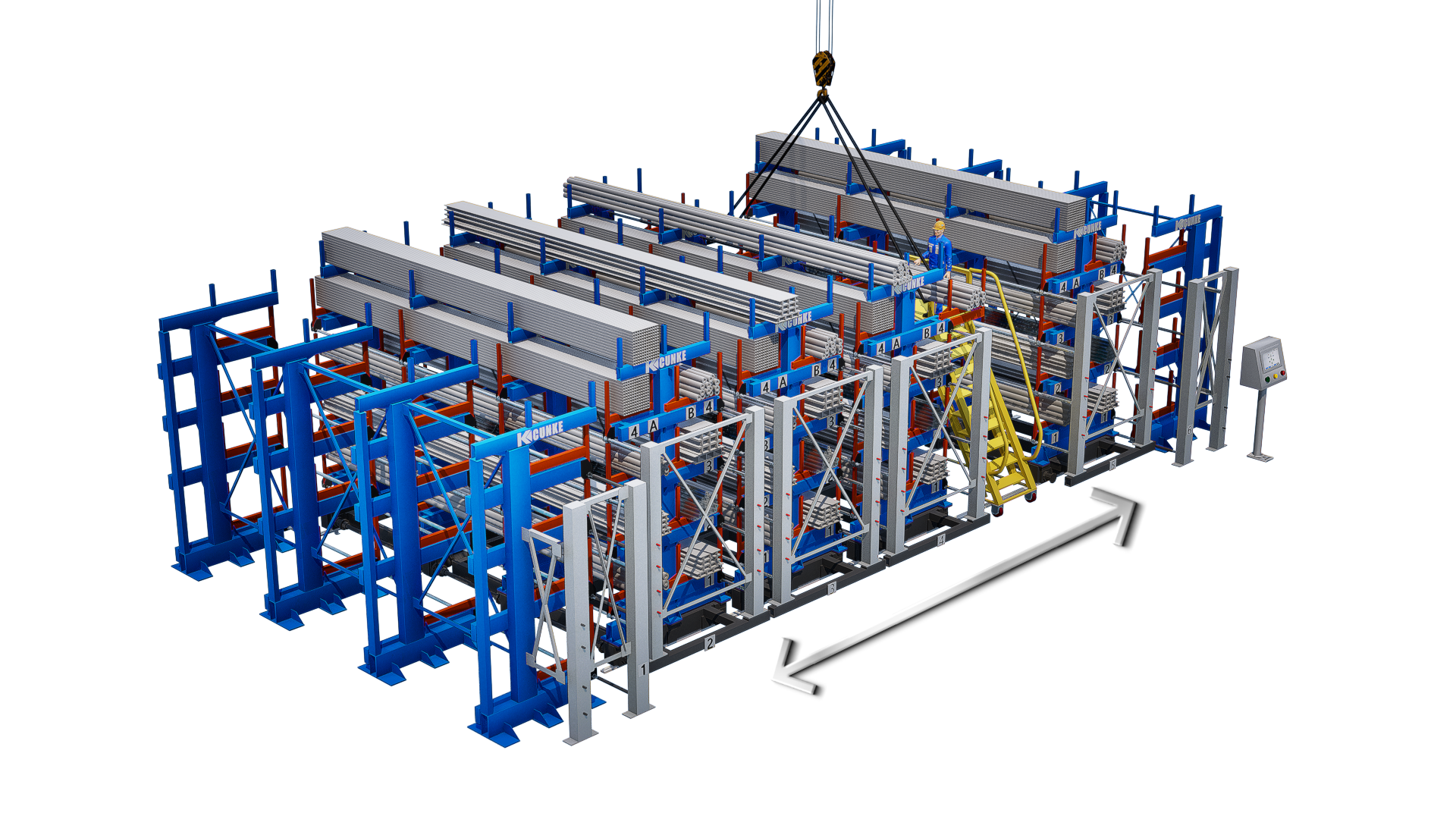

Paired with telescopic arms, the Mobile Roll-Out Cantilever Rack allows overhead crane operators to load and unload materials directly and efficiently—saving time, improving safety, and increasing density.

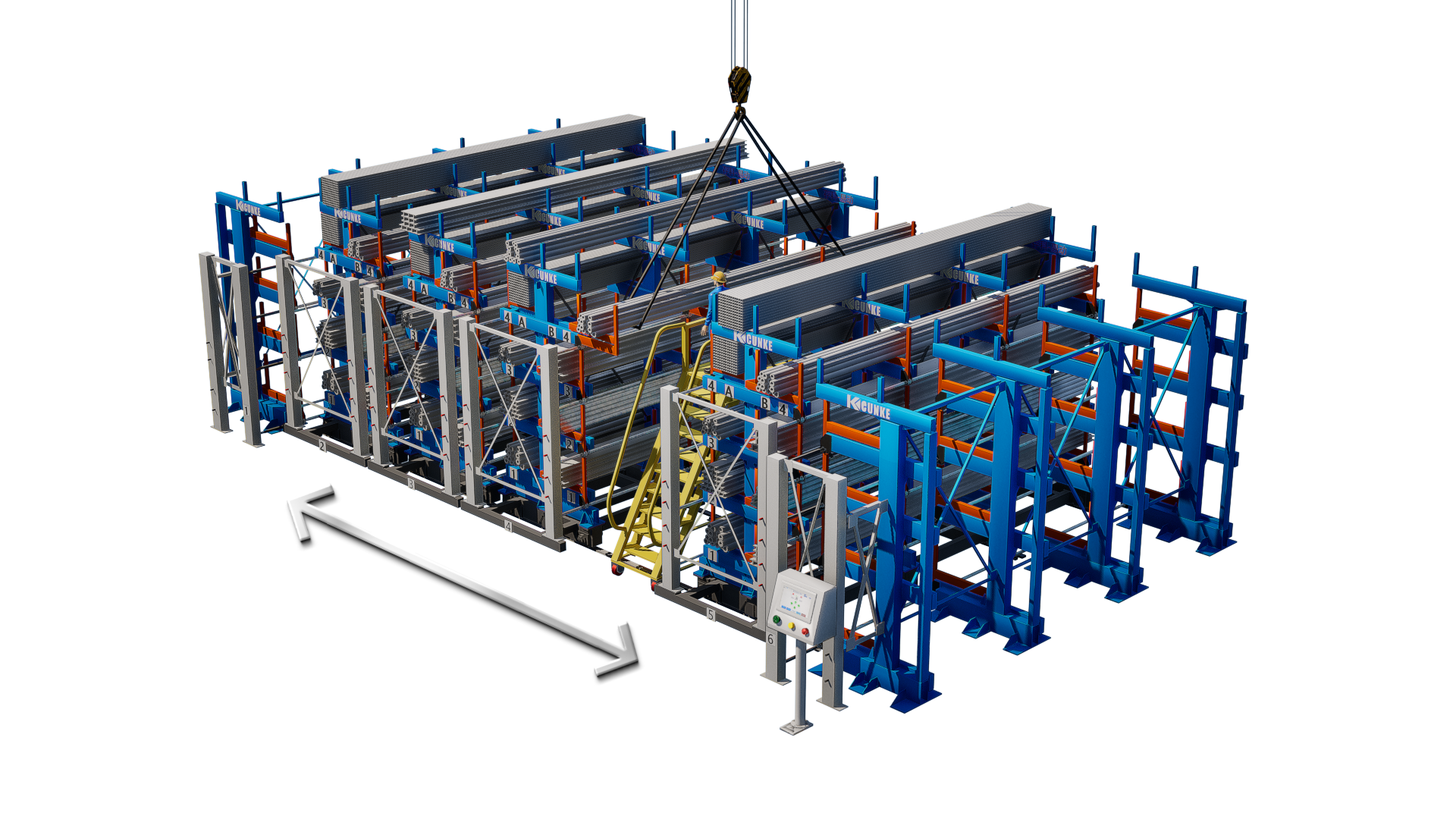

The foundation of the system is the motorized mobile base that slides laterally on embedded rails.

The movement is powered by electric motors and controlled by distributed or centralized panels

Unlike fixed cantilever racks, each arm extends outward smoothly for easy access to stored material.

Each system is tailored based on your storage needs, facility layout, and material dimensions.

The Mobile Roll-Out Cantilever Rack places worker safety at the center of its design:

This rack is widely used in:

It’s the ideal solution for operations needing:

By replacing traditional floor stacking or fixed racks, customers have reported:

The Mobile Roll-Out Cantilever Rack helps you turn wasted floor space into efficient, safe, and productive storage. Whether you’re upgrading from fixed racks or designing a new facility, we’ll tailor the solution to fit your needs.